Dissolving pulp production

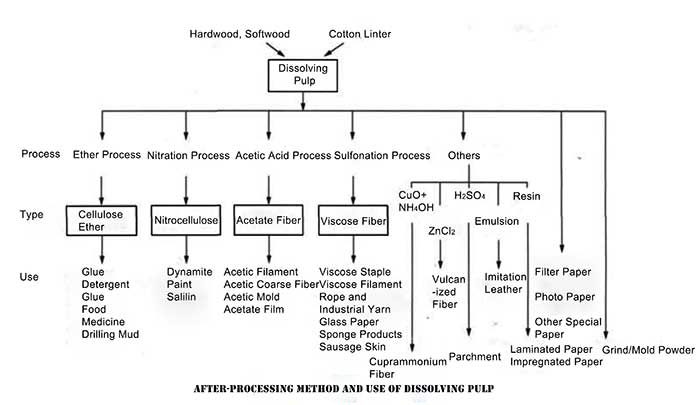

The dissolving pulp can be made through various production methods and raw materials. It includes many categories of products and has wide applications. The cooking processes of dissolving pulp include sulfite process, sulfate pre-hydrolysis process, alkali process, alkali pre-hydrolysis process, etc.

The raw materials of dissolving pulp include softwood and hardwood. The non-wood fibers can be also used, especially like cotton linter, bamboo fiber and so on. In foreign countries, wood is basically used as raw material for the production of dissolving pulp. During the earliest period, softwood is adopted and then the hardwood done. In China, cotton linter is mainly used as raw material for dissolving pulp production. Only a small amount of dissolving pulp is produced by sulfite cooking process with hardwood or a mixture of hardwood and softwood. In recent years, it is in blooming development that the dissolving pulp is produced by sulfate cooking process through the raw materials of hardwood, softwood and bamboo. This process has been replaced sulfite cooking process gradually. The proportion dissolving pulp produced by the process is also greatly improved.

The use and market distribution of dissolving pulp

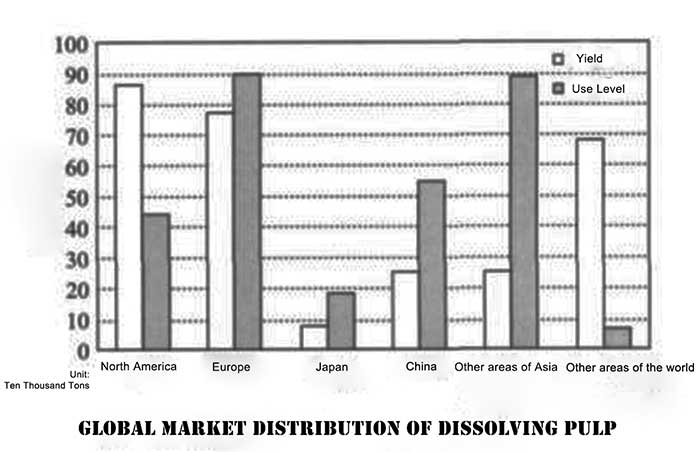

North America and South Africa (hereinafter referred to as other countries and regions in the world) is main export areas of dissolving pulp. Asia is the world's largest net import area, Europe second. In 2005, the global market distribution of dissolving pulp is as shown in the bar chart below.

Currently China is the main concentrated area of production capacity growth of viscose fiber in the world. The annual viscose fiber yield in China makes a double-digit growth in recent years. In 2005, viscose fiber yield is about 1120,000 tons, accounting for 40.3% of the total yield of global viscose fiber.

The uses and alternative products of dissolving pulp are shown in Table 1

| Common Use | Alternative Products | |

|---|---|---|

|

Cellulose Acetate |

Cigarette Filter | Paper, Cotton Yarn |

| High Quality Plastic | Synthetic Fiber | |

| Film | Synthetic Thin Film | |

| Acetate Fiber | Plastic | |

| Natural Silk, Cotton | ||

|

Cellulose Ether, Other |

Explosive | Mixture |

| The food industry | Cotton Linter Pulp | |

| Drugs | Synthetic Fiber | |

| Cosmetics | Bleached Sulfite Pulp (Low Content of Alpha Cellulose CMC) | |

| Special Paint | ||

| Glue | ||

| Artificial Leather | ||

|

Viscose Fiber |

Viscose Fiber | |

| Textile Industry | Mixture | |

| Rope and Industrial Yarn | Cotton Linter Pulp | |

| Cellophane | Synthetic Fiber | |

| Sausage Skin | Bleached Sulfite Pulp (Low Content of Alpha Cellulose CMC) | |

| Sponge |

The development history of dissolving pulp

With different cooking chemicals, main processes of dissolving pulp can be divided into sulfite process, sulfate pre-hydrolysis process, alkali process (also called caustic soda process) and alkali pre-hydrolysis process.

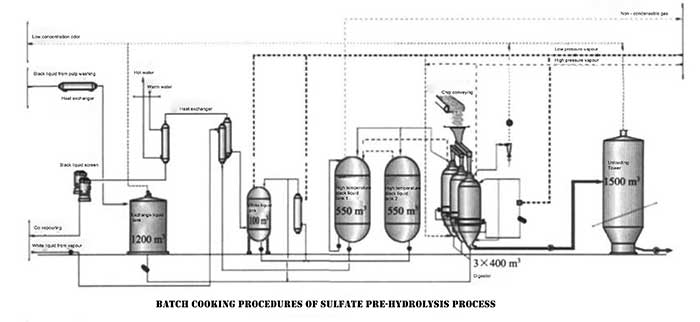

The current pulping process

Due to environmental protection, the making process of dissolving pulp is mainly sulfate pre-hydrolysis process. Batch digesters can be used to it. Of course, the other sulfate pre-hydrolysis processes are still applied in the pulping industry, such as Lenzing CBC, G&LV super batch process from Metso. In theory, digesters can be batch type or continuous type. Andritz Company and Kvaerner Company are well known for continuous digester. Kvaerner recently have individual dissolving pulp production line adopts continuous digester. In China, there are several companies that begin to adopt continuous digester from Andritz Company to produce Eucalyptus dissolving pulp.