As we all know, paper is made from trees. It is hard to image how trees can be turned into papers. Now let’s have a look at the process of making paper from trees.

As a matter of fact, the cell walls of trees are full of cellulose fibres, which are stuck together with natural glue called “lignin”. Briefly speaking, when the lignin is removed and the cellulose fibers are separated and reorganized, paper can be made. Now let’s see the paper making process in detail.

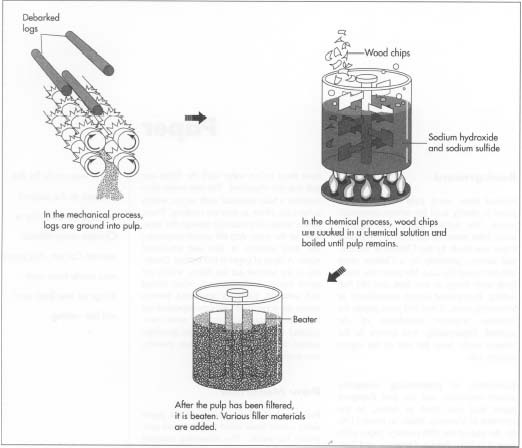

Step 1. Making Paper Pulp

To make paper from trees, the raw wood material should be turned into pulp firstly. The pulp is made of wood fibers and chemicals that are mixed together. They can be processed either mechanically or chemically. For the mechanical process, logs are firstly tumbled in drums to remove the bark. Then logs are sent to grinders, which break wood down into pulp by pressing it between huge revolving slabs. After this, the pulp is filtered in order to remove foreign objects. For the chemical process, wood chips from de-barked logs are cooked in a chemical solution. This is done in huge vats called digesters. The chips are fed into the digester and then boiled at high pressure in a solution of sodium hydroxide and sodium sulfide.

The wood chips dissolve into pulp in the solution. Next the pulp is sent through filters. Bleach may be added at this stage, or colorings. The pulp is sent to the paper plant.

Step 2. Pulp Beating

The pulp is put through a pounding and squeezing process called beating, appropriately enough. Inside a large tub, the pulp is subjected to the effect of machine beaters. At this point, various filler materials can be added such as chalks, clays, or chemicals such as titanium oxide. These additives will influence the opacity and other qualities of the final product.

Sizing is also added at this point. Sizing affects the way in which paper reacts with various inks. Without any sizing at all, a paper will be too absorbent for most uses except as a desk blotter. A sizing such as starch makes the paper resistant to water-based ink (inks actually sit on top of a sheet of paper, rather than sinking in). A variety of sizings, generally rosins and gums, are available depending on the eventual use of the paper. Paper that receives a printed design, such as gift wrapping, requires a particular formula of sizing that will make the paper accept the printing properly.

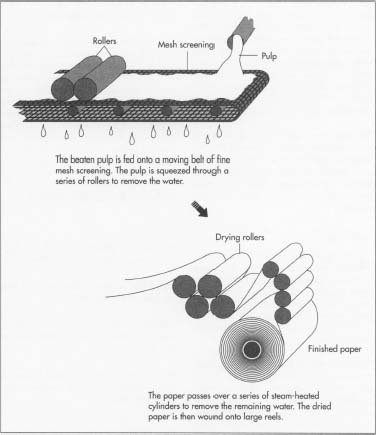

Step 3. Pulp to Paper

Pulp is fed or pumped into giant, automated machines. One common type is called Fourdrinier machine, which was invented in England in 1807. Pulp is fed into the Fourdrinier machine on a moving belt of fine mesh screening. The pulp is squeezed through a series of rollers, while suction devices below the belt drain off water. If the paper is to receive a water mark, a device called a dandy moves across the sheet of pulp and presses a design into it.

The paper then moves onto the press section of the machine, where it is pressed between rollers of wool felt. The paper then passes over a series of steam-heated cylinders to remove the remaining water.

Step 4. Paper Finishing

The dried paper is wound onto large reels, where it will be further processed according to its ultimate use. Paper is smoothed and compacted further by passing through metal rollers called calendars. A particular finish, whether soft and dull or hard and shiny, can be imparted by the calendars. The paper may be further finished by passing through a vat of sizing material. It may also receive a coating, which is either brushed on or rolled on. Coating adds chemicals or pigments to the paper's surface, supplementing the sizings and fillers earlier in the process. Fine clay is often used as a coating. The paper may be supercalendered next. Then the paper is cut to the desired size.