The Principle of How is Wind Energy Produced

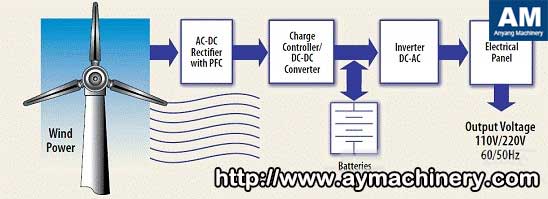

Before talking about the wind tower construction, it is necessary to understand the principle of how is wind energy produced. The principle of wind energy generation is to use wind to drive the rotation of the windmill blades, and then increase the speed of the rotation through booster engine to promote the generator to produce electricity. According to the current technology, about three meters per second of wind speed (the degree of the breeze) can start producing electricity.

Wind Energy Equipment in the Wind Tower Construction

Wind energy technology equipments are the important part, the basis and guarantee for wind power industry and its development. The equipment can be mainly divided into three parts, specifically including:

- Rotating equipment: booster engine, electric generator, rotor blade, main shaft, high speed shaft, low speed shaft, etc.

- Functional systems: electronic controller, hydraulic system, yawing device, anemograph, wind indicator, etc.

What is Wind Tower Construction

Wind tower is used to carry all the equipments such as the nacelle and electric generator. It is the supporting tower of wind power generation, which plays a supporting role in the wind turbine and absorbs the vibration of the machines. Usually the taller towers have the advantages. The higher the ground is from, the greater the wind speed is. It is now generally a tubular tower that is safer for maintenance personnel as they can reach the top of the tower through an internal ladder. The structure of wind tower includes: a basic embedded parts, a tower bottom platform, a bottom tower section, a middle tower section, and a top tower section. The basic embedded parts include: base ring and its supporting legs. There are inverters and main control cabinets on the platform of the tower bottom. The bottom tower section, the middle tower section and the top tower section include their own ladders, cable racks and platforms.

The production process of wind power tower is generally as follows: CNC cutting machine for material treatment, thick steel plates for opening the groove, spot welding and positioning after the forming by the coiling machine, the welding of the inner and outer longitudinal joints after confirmation, have the second roundness after roundness inspection If necessity. After the single-section cylinder is welded, the hydraulic group is used to perform group-to-spot welding on the roller frame. And then the inner and outer ring seams are welded, and the straightness is checked after the tolerance is checked. After welding the flanges, the non-destructive testing and flatness inspection shall be carried out. After the sand blasting, painting treatment, the internal parts installation and finished product inspection, the whole wind tower will be transported to the installation site.

In short, the wind tower construction can be described as follows:

Accurate cutting by CNC——High-efficiency roll forming process——High quality automatic welding process——All-round quality inspection——fine sand blasting——Multi-layer anti-corrosion painting process——High requirements safe transportation ——Installation on site.

Our CNBM Company has its own product design research and development center, and the provincial technology center, technical cooperation with domestic and foreign advanced institutions at the same time, cutting, welding, machining, boutique, spraying, such as mechanical and electrical repair six modern production line workshop, the configuration of the international advanced production equipment, fully implement the national standard quality management system, industry leading production, really lead the industry trend.

Company's products mainly include wind tower, the sea wind tower and basic structure, manufacture of petrochemical equipment, etc., wonderful product, advanced manufacturing technology and strong production capacity, meet all kinds of pressure vessel manufacture and the requirement of large scale wind tower.